Admin

مدير المنتدى

عدد المساهمات : 18996

التقييم : 35494

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: بحث بعنوان Fiber prestressed polymer-matrix composites - a review موضوع: بحث بعنوان Fiber prestressed polymer-matrix composites - a review  الجمعة 05 فبراير 2021, 1:03 am الجمعة 05 فبراير 2021, 1:03 am | |

|

أخوانى فى الله

أحضرت لكم كتاب

بحث بعنوان

Fiber prestressed polymer-matrix composites - a review

Nawras H Mostafa1,2, ZN Ismarrubie2, SM Sapuan2,3 and

MTH Sultan4

و المحتوى كما يلي :

Abstract

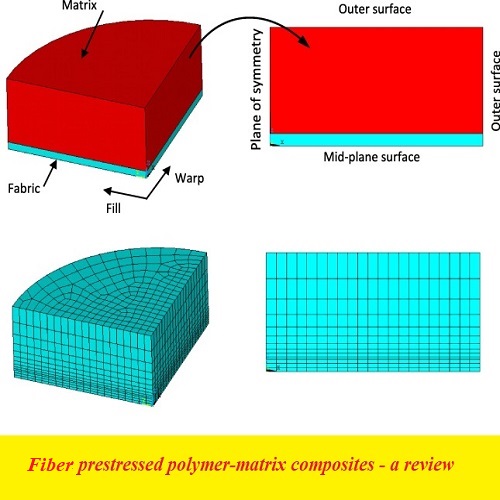

This article reviews the literature studies based on improving the mechanical properties of fibre-reinforced composites

using fibre-prestressing method. The idea is characterized by pretensioning the fibres either elastically or viscoelastically

prior matrix curing. The beginnings of the studies in this field were focused on reducing fibre waviness and breaking the

weaker fibres by pretensioning the fibres to a relatively high stress level prior moulding process. In the last three decades,

the concept of fibre prestressing had been developed to include its ability to reduce the effect of undesired residual

stresses existence accompanying manufacturing process of fibre-reinforced composites. The main advantage of fibre

prestressing method is to generate a desired and controlled residual stress state within the matrix in order to obstruct

the initiation and propagation of cracks. Various techniques of fibre prestressing have been reviewed to show their scope

of applications, developments and limitations. Therefore, the findings drawn from this review can be used for further

studies in the field of fibre prestressed composites in order to select the most suitable methodology and develop it to fit

the manufacturing process requirements towards a production of high-performance composites without a considerable

additional cost.

Keywords

Fibre pretension, polymeric matrix composites, prestressing method, microcracks, residual stresses

Conclusions

This review article attempted to cover most studies

related to fibre prestressing method and its developments. Initially, the fibre pretension method was used

to decrease the fibre waviness and then after to detect

and break the weak fibres before moulding it into the

resin. Therefore, the structural properties of the final

product were enhanced by eliminating the negative

effect of weak fibre’s existence. Subsequently, the idea

of the fibre pretension was extended to include its benefits for obstructing the matrix cracking and its development. The focus was related directly to minimize the

generated residual stresses during fabrication processes.

The existence of tensile residual stress affects the composite structural performance directly and becomes

more detrimental when the composites are subjected

to external loading than the unloaded ones during service life.

The interest in the subject began since 1968, which

included structural properties like tensile modulus,

tensile strength, flexural modulus, flexural strength,

compressive modulus, compressive strength, fatigue

and impact toughness. The overall effects of fibre

pre-stressing on these structural properties were positive. Several mechanisms were attributed to enhance the

PMC’s structural properties. These mechanisms are (i)

generating compressive residual stresses within the

matrix upon releasing the fibre pretension and this

makes the matrix more resistant to cracks initiation

and propagation, (ii) improving the architecture of

the yarns to become straighter and tighter, thereby

the load is instantaneously transferred from matrix to

the fibre, (iii) breaking the weaker fibres prior moulding

process, (iv) adapting the composite to absorb more

impact energy by increasing the fibre-matrix debonding

damage and (v) creating a transverse force opposite to

bending load. For various composite systems used in

the previous studies, a maximum increase in the structural properties was recorded to range up to 10–60%

(tensile modulus) and 15–140% (tensile strength), 10–

50% (flexural modulus) and 10–67% (flexural

strength), 9% (compressive strength), 25–62%

(impact strength) and 43–200% (fatigue life).

Although fibre prestressing can significantly improve

structural properties, there are potential disadvantages.

In case of EFPPMCs type, the main disadvantages or

restrictions are its complexity to apply for non-flat constructions, the applied prestress value is a function of

plies number that formed the composite

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل بحث بعنوان Fiber prestressed polymer-matrix composites - a review

رابط مباشر لتنزيل بحث بعنوان Fiber prestressed polymer-matrix composites - a review

|

|