Admin

مدير المنتدى

عدد المساهمات : 18992

التقييم : 35482

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

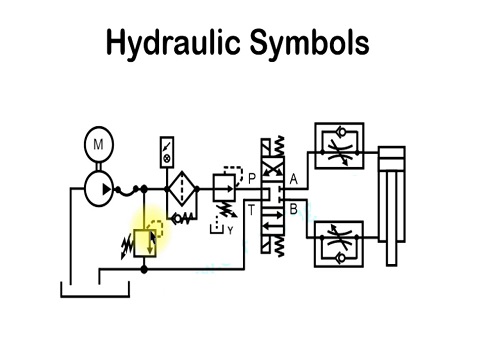

|  موضوع: تجميعه رموز الدوائر الهيدروليكية - Pooyan Hydraulics - Basic Symbols موضوع: تجميعه رموز الدوائر الهيدروليكية - Pooyan Hydraulics - Basic Symbols  الخميس 26 مايو 2022, 6:39 pm الخميس 26 مايو 2022, 6:39 pm | |

|

أخواني في الله

أحضرت لكم كتاب

و المحتوى كما يلي :

تجميعه رموز الدوائر الهيدروليكية

Pooyan Hydraulics - Basic Symbols

2) L= Length of dash, E = Thickness of line, D = Space between lines

DESCRIPTION SYMBOL APPLICATION

BASIC SYMBOLS

Line

- continuous

- long dashes

- short dashes

- double

- long chain thin

(optional use)

Circle, semi-circle

mechanical connections (shafts, levers, pistonrods)

Enclosure for several components assembled

in one unit

As a rule, energy conversion units (pump,

compressor, motor)

Measuring instruments

Non-return link, roller, etc

Mechanical link, roller, etc.

Semi-rotary actuator

E } flow lines

DESCRIPTION SYMBOL APPLICATION

d d ≈ 5E

Square, rectangle

Diamond

Miscellaneous

symbols

Triangle:

- solid

- in outline only

Arrow

Sloping arrow

FUNCTIONAL

SYMBOLS

As a rule, control valves (valve) except for nonreturn valves

Conditioning apparatus (filter, separator,

lubricator, heat exchanger)

Flow line connection

Spring

Restriction:

- affected by viscosity

- unaffected by viscosity

The direction of flow and the nature of the fluid

Hydraulic flow

Pneumatic flow or exhaust to atmosphere

Indication of:

- direction

- direction of rotation

- path and direction of flow through valves.

For regulating apparatus as in 3.4 both

representations, with or without a tail to the

end of the arrow, are used without distinction

As a general rule the line perpendicular to the

head of the arrow indicates that when the

arrow moves, the interior path always remains

connected to the corresponding exterior path

Indication of the possibility of a regulation or a

progressive variabilityI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

OUTLET

INLET

BALL CHECK

U

PUMPS AND

COMPRESSORS

Fixed capacity

hydraulic pump:

- with one

direction of flow

- with two

directions of flow

Variable displacement

hydraulic pump:

- with one

direction of flow

- with two

directions of flow

Fixed capacity

compressor (always

one direction of flow)

To convert mechanical

energy into hydraulic or

pneumatic energy.

The symbol is a

combination of 2.1.1.1

and 1.2.3 (sloping

arrow)

The symbol is a

combination of 2.1.1.2

and 1.2.3 (sloping

arrow)I S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

SPRING

To convert hydraulic or

pneumatic energy into rotary

mechanical energy

The symbol is a combination of

2.2.1.1 and 1.2.3 (sloping arrow)

The symbol is a combination of

2.2.1.2 and 1.2.3 (sloping arrow)

The symbol is a combination of

2.2.3.1 and 1.2.3 (sloping arrow)

The symbol is a combination of

2.2.3.2 and 1.2.3 (sloping arrow)

MOTORS

Fixed capacity

hydraulic motor:

- with one

direction of flow

- with two

directions of flow

Variable displacement

hydraulic motor:

- with one

direction of flow

- with two

directions of flow

Fixed displacement

pneumatic motor:

- with one

direction of flow

- with two

directions of flow

Variable displacement

hydraulic motor:

- with one

direction of flow

- with two

directions of flow

Oscillating motor:

- hydraulic

- pneumatic

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOLI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

PUMP/MOTOR UNITS

Fixed displacement

pump/motor unit:

- with reversal of the

direction of flow

- with one single

direction of flow

- with two directions

of flow

Variable displacement

pump/motor unit:

- with reversal of the

direction of flow

- with one single

direction of flow

- with two directions

of flow

VARIABLE SPEED DRIVE

UNITS

CYLINDERS

Single acting cylinder:

- returned by an

unspecified force

- returned by spring

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

Unit with two functions,

either as pump or as rotary

motor

Functioning as pump or

motor according to direction

of flow

Functioning as pump or

motor without change of

direction of flow

Functioning as pump or

motor with either direction of

flow

The symbol is a combination

of 2.3.1.1 and 1.2.3 (sloping

arrow)

The symbol is a combination

of 2.3.1.2 and 1.2.3 (sloping

arrow)

The symbol is a combination

of 2.3.1.3 and 1.2.3 (sloping

arrow)

Torque converter. Pump

and/or motor are variable

capacity. Remote drives, see

8.2

Equipment to convert

hydraulic or pneumatic

energy into linear energy

Cylinder in which the fluid

pressure always acts in one

and the same direction (on

the extension stroke)

General symbol when the

method of return is not

specified

Combination of the general

symbols 2.5.1.1 and 1.1.5.2

(spring)

Detailed SimplifiedI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

Double acting cylinder:

- with single piston

rod

- with double-ended

piston rod

Differential cylinder

Cylinder with cushion:

- with single fixed

cushion

- with double fixed

cushion

- with single

adjustable cushion

- with double

adjustable cushion

Telescopic cylinder:

- single acting

- double acting

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

Cylinder in which pressure

fluid operates alternately in

both directions (extend and

retract strokes)

The action is dependent on

the difference between the

effective areas on each side

of the piston

Cylinder incorporating fixed

cushion acting in one

direction only

Cylinder with fixed cushion

acting in both directions

The symbol is a

combination of 2.5.4.1 and

1.2.3 (sloping arrow)

The symbol is combination

of 2.5.4.2 and 1.2.3

(sloping arrow)

The fluid pressure always

acts in one and the same

direction (on the extend

stroke)

The fluid pressure operates

alternately in both

directions (extend and

retract strokes)I S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

PRESSURE

INTENSIFIERS:

- for one type of fluid

- for two types of

fluid

AIR-OIL ACTUATOR

METHOD OF

REPRESENTATION OF

VALVES (EXCEPT 7.3

AND 7.6)

One single square

Two or more squares

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

CONTROL

VALVES

Detailed Simplified

Equipment transforming a

pressure x into a higher

pressure y

E.g. a pneumatic pressure x is

transformed into a higher

pneumatic pressure y

E.g. a pneumatic pressure x is

transformed into a higher

hydraulic pressure y

Equipment transforming a

pneumatic pressure into a

substantially equal hydraulic

pressure or vice versa

Made up of one or more

squares 1.1.3 and arrows

In circuit diagrams hydraulic

and pneumatic units are

normally shown in the

unoperated condition

Indicates unit for controlling

flow or pressure, having in

operation and infinite number

of possible positions between

its end positions so as to vary

the conditions of flow across

one or more of its ports, thus

ensuring the chosen pressure

and/or flow with regard to the

operating conditions of the

circuit

Indicate a directional control

valve having as many distinct

positions as there are

squares. The pipe

connections are normally

represented as representing

the unoperated condition (see

3.1). The operating positions

are deduced by imagining the

boxes to be displaced so that

the pipe connections

correspond with the ports of

the box in questionI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

Simplified symbol for

valves in cases of

multiple repetition

DIRECTIONAL

CONTROL VALVES

Flow paths:

- one flow path

- two closed ports

- two flow paths

- two flow paths

and one closed port

- two flow paths

with cross connection

- one flow path in a

bypass position, two

closed ports

Non-throttling

directional control

valve

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

3 The number refers to a note

on the diagram in which the

symbol for the valve is given

in full

Units providing for the

opening (fully or restricted)

or the closing of one or

more paths (represented by

several squares)

Square containing interior

lines

The unit provides distinct

circuit conditions each

depicted by a square

Basic symbol for 2-position

directional control valve

Basic symbol for 3-position

directional control valve

A transitory but significant

condition between two

distinct positions is

optionally represented by a

square with dashed endsI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

Designation: The first

figure in the

designation shows the

number of ports

(excluding pilot ports)

and the second figure

the number of distinct

positions

Directional control

valve 2/2:

- with manual control

- controlled by

pressure operating

against a spring (e.g.,

on air unloading valve)

Directional control valve

3/2:

- controlled by

pressure in both

directions

- controlled by

solenoid with return

spring

Directional control

valve 4/2:

- controlled by

pressure in both

directions by means of

pilot valve (with single

solenoid and spring

return)

Directional control

valve 5/2:

- controlled by

pressure in both

directions

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

Detailed

Simplified

Directional control valve

with 2 ports and 2 distinct

positions

Directional control valve

with 3 ports and 2 distinct

positions

Indicating an intermediate

condition (see 3.2.2.3)

Directional control valve

with 4 ports and 2 distinct

positions

Directional control valve

with 5 ports and 2 distinct

positionsI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

Throttling directional

control

- with 2 ports (one

throttling orifice)

- with 3 ports (two

throttling orifices)

- with 4 ports (four

throttling orifices)

Electro-hydraulic

servo valve:

Electro-pneumatic

servo valve:

- single-stage

- two-stage with

mechanical feedback

- two-stage with

hydraulic feedback

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

T B P A T

Torque motor

armature

Torque motor

Spool

The unit has 2 extreme

positions and an infinite

number of intermediate

conditions with varying

degrees of throttling

All the symbols have

parallel lines along the

length of the boxes. For

valves with mechanical

feedback see 5.3

Showing the extreme

positions

Showing the extreme

positions and a central

(neutral) position

For example: Tracer valve

plunger operated against a

return spring

For example: Directional

control valve controlled by

pressure against a return

spring

For example: Tracer valve,

plunger operated against a

return spring

A unit which accepts an

analog electrical signal and

provides a similar analog

fluid power output

- with direct operation

- with indirect pilot

operation

- with indirect pilot

operationI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

NON-RETURN VALVES,

SHUTTLE VALVE,

RAPID EXHAUST

VALVE

Non-return valve

- free

- spring loaded

- pilot controlled

- a pilot signal

closes the valve

- a pilot signal

opens the valve

- with restriction

Shuttle valve

Rapid exhaust valve

PRESSURE CONTROL

VALVES

Pressure control valve:

- 1 throttling orifice

normally closed

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

P

Outlet

Drain

Pilot

Valves which allow free flow

in one direction only

Opens if the inlet pressure is

higher than the outlet

pressure

Opens if the inlet pressure is

greater than the outlet

pressure plus the spring

pressure

As 3.3.1.1 but by pilot control

it is possible to prevent

Unit allowing free flow in one

direction but restricted flow

in the other

The inlet port connected to

the higher pressure is

automatically connected to

the outlet port while the other

inlet port is closed

When the inlet port is

unloaded the outlet port is

freely exhausted

Units ensuring the control of

pressure. Represented by one

single square as in 3.1.1 with

one arrow (the tail to the

arrow may be placed at the

end of the arrow). For interior

controlling conditions see

5.2.4.3

General symbolsI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

- 1 throttling orifice

normally open

- 2 throttling

orifices, normally

closed

Pressure relief valve

(safety valve):

- with remote pilot

control

Proportional pressure

relief

Sequence valve

Pressure regulator or

reducing valve

(reducer of pressure):

- without relief port

- without relief port

with remote control

- with relief port

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

System

T

P T

Outlet

P T

Outlet

Inlet pressure is controlled

by opening the exhaust port

to the reservoir or to

atmosphere against an

opposing force (for example

a spring)

The pressure at the inlet

port is limited as in 3.4.2 or

to that corresponding to the

setting of a pilot control

Inlet pressure is limited to a

value proportional to the

pilot pressure (see

5.2.4.1.3)

When the inlet pressure

overcomes the opposing

force of the spring, the valve

opens permitting flow from

the outlet port

A unit which, with a

pressure variable inlet

pressure, gives substantially

constant output pressure

provided that the inlet

pressure remains higher

than the required outlet

pressure

As in 3.4.5.1, but the outlet

pressure is dependent on

the control pressureDESCRIPTION SYMBOL

- with relief port,

with remote control

Differential pressure

regulator

Proportional pressure

regulator

FLOW CONTROL

VALVES

Throttle valve:

- with manual

control

- with mechanical

control against a

return spring (braking

valve)

Flow control valve:

- with fixed output

- with fixed output

and relief port to

reservoir

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

I S O F L U I D P O W E R G R A P H I C S Y M B O L S

Detailed Simplified

Inlet Outlet

Inlet Outlet

Fixed orifice

Control orifice

As in 3.4.5.3, but the outlet

pressure is dependent on the

control pressure

The outlet pressure is

reduced by a fixed amount

with respect to the inlet

pressure

The outlet pressure is

reduced by a fixed ratio with

respect to the inlet pressure

(see 5.2.4.1.3)

Units ensuring control of

flow excepting 3.5.3

positions and method of

representation as 3.4

Simplified symbol (does not

indicate the control method

or the state of the valve)

Detailed symbol (indicates

the control method of the

state of the valve)

Variations in inlet pressure

do not affect the rate of flow

As 3.5.2.1 but with relief for

excess flow

1998/1999 Fluid Power Handbook & Directory A/239DESCRIPTION SYMBOL

- with variable

output

- with variable

output and relief port

to reservoir

Flow dividing valve

SHUT-OFF VALVE

SOURCES OF ENERGY

Pressure source

Hydraulic pressure

source

Pneumatic pressure

source

Electric motor

Heat engine

FLOW LINES AND

CONNECTIONS

Flow line:

- working line,

return line and feed

line

- pilot control line

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

I S O F L U I D P O W E R G R A P H I C S Y M B O L S

M M

Control chamber

Vent connection

Inlet

Tank

Outlet

As 3.5.2.1 but with

arrow 5.2.3 added to the

symbol of restriction

As 3.5.2.3 but with relief

for excess flow

The flow is divided into

two flows in a fixed ratio

substantially

independent of pressure

variations

Simplified symbol

Simplified general

symbol

Symbols to be used

when the nature of the

source should be

indicated

Symbol 113 in IEC

Publication 117.2

A/240

ENERGY TRANSMISSION AND CONDITIONINGI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

- drain or bleed line

- flexible pipe

- electric line

Pipeline junction

Crossed Pipelines

Air bleed

Exhaust port:

- plain with no

provision for

connection

- threaded for

connection

Power take-off:

- plugged

- with take-off line

Quick-acting coupling:

- connected, without

mechanically opened

non-return valve

- connected, with

mechanically opened

non-return valves

- uncoupled, with

open end

- uncoupled, closed

by free non-return

valve (see 3.3.1.1)

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

Flexible hose, usually

connecting moving parts

not connected

On equipment or lines, for

energy take-off or measurementI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

Rotary connection:

- one way

- three way

Silencer

RESERVOIRS

Reservoir open to

atmosphere:

- with inlet pipe

above fluid level

- with inlet pipe

below fluid level

- with a header line

Pressurized reservoir

ACCUMULATORS

FILTERS, WATER

TRAPS, LUBRICATORS

AND MISCELLANEOUS

APPARATUS

Filter or strainer

Water trap

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

Air or gas

Bowl

Filer

element

Line junction allowing angular

movement in service

The fluid is maintained under

pressure by a spring, weight

or compressed gas (air,

nitrogen, etc.)I S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

- with manual

control drain

- automatically

drained

Filter with water trap:

- with manual

control

- automatically

drained

Air dryer

Lubricator

Conditioning unit

- Detailed symbol

- Simplified symbol

HEAT EXCHANGERS

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

Float

Desiccant

Inlet air

Lubricated

air

Combination of 4.5.1 and

4.5.2.1

Combination of 4.5.1 and

4.5.2.2

A unit drying air (for

example, by chemical

means)

Small quantities of oil are

added to the air passing

through the unit, in order

to lubricate equipment

receiving the air

Consisting of filter,

pressure regulator,

pressure gage and

lubricator

Apparatus for heating or

cooling the circulating

fluidI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

Temperature controller

Cooler

Heater

Mechanical

components

Rotating shaft:

- in one direction

- in either direction

Detent

Locking device

Over-center device

Pivoting devices:

- simple

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

The fluid temperature is

maintained between two

predetermined values. The

arrows indicate that heat

may be either introduced or

dissipated

The arrows in the diamond

indicate the extraction of heat

- without representation of

the flow lines of the coolant

- indicating the flow lines

of the coolant

The arrows in the diamond

indicate the introduction of

heat

The arrow indicates rotation

A device for maintaining a

given position

* The symbol for unlocking

control is inserted in the

square

Prevents the mechanism

from stopping in a dead

center position

CONTROL MECHANISMSI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

- with traversing

lever

- with fixed fulcrum

CONTROL METHODS

Muscular control:

- by pushbutton

- by lever

- by pedal

Mechanical control:

- by plunger or

tracer

- by spring

- by roller

- by roller, operating

in one direction only

Electrical control:

- by solenoid

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

The symbols representing control

methods are incorporated in the

symbol of the controlled

apparatus, to which they should be

adjacent. For apparatus with

several squares the actuation of

the control makes effective the

square adjacent to it.

General symbol (without indication

of control type)

- with one winding

- with two windings operating in

opposite directionsI S O F L U I D P O W E R G R A P H I C S Y M B O L S

DESCRIPTION SYMBOL

- by electric motor

Control by application

or release of pressure

Direct acting control:

- by application of

pressure

- by release of

pressure

- by different control

areas

Indirect control, pilot

actuated:

- by application of

pressure

- by release of

pressure

Interior control paths

Combined control:

- by solenoid and

pilot directional valve

- by solenoid or pilot

directional valve

USE OF THE EQUIPMENT

OR EXPLANATION OF THE SYMBOL

M

- with two windings operating in

a variable way progressively,

operating in opposite direction

In the symbol the larger rectangle

represents the larger control area,

i.e., the priority phase

General symbol for pilot

directional control valve

The control paths are inside the

unit

The pilot directional valve is

actuated by the solenoid

Either may actuate the control

independently

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل تجميعه رموز الدوائر الهيدروليكية - Pooyan Hydraulics - Basic Symbols

رابط مباشر لتنزيل تجميعه رموز الدوائر الهيدروليكية - Pooyan Hydraulics - Basic Symbols

|

|