Admin

مدير المنتدى

عدد المساهمات : 18996

التقييم : 35494

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: محاضرة بعنوان Milling Operations - TA 102 Workshop Practice موضوع: محاضرة بعنوان Milling Operations - TA 102 Workshop Practice  الأحد 18 ديسمبر 2022, 9:29 pm الأحد 18 ديسمبر 2022, 9:29 pm | |

|

أخواني في الله

أحضرت لكم

محاضرة بعنوان

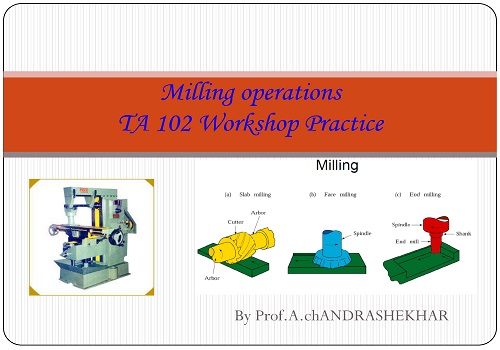

Milling Operations - TA 102 Workshop Practice

By Prof. A. chANDRASHEKHAR

و المحتوى كما يلي :

- Milling machines are used to produce parts having flat as well as

curved shapes.

- Milling machines are capable of performing the usual flat,

horizontal and vertical machining operations and can be used to

do many other machining operations like gear teeth cutting,

drilling, reaming, boring, slotting, tapping, keyway cutting, cam

milling and so forth.

- In this process, the work piece is normally fed into a rotating

cutting tool known as milling cutter. Equally spaced peripheral

teeth on the cutter come in contact with the work piece

intermittently and machine the work piece.- In conventional milling operation, metal is cut as the work piece

is fed against a rotating multi point cutter.

- Different types of cutters are used in milling like end mill cutter,

side and face cutter machine, form cutter and so forth.The Milling Machine

- Two types of milling machines are common. They are

distinguished by the orientation of the axis of rotation of the

spindle of the cutter.

- In horizontal milling machine, the axis of the spindle in

horizontal and

- In vertical milling machine the axis of the spindle is vertical.Horizontal Knee and Column type milling

machine

- Principal parts

i. Base

ii. Column

iii. Knee

iv. Saddle

v. Table

vi. Over arm

vii. Spindle, and

viii. arborVertical Knee and column type milling

machine

- A horizontal milling

machine can be converted in

to a vertical milling machine

by removing the arbor and

attaching a vertical milling

attachment to the spindle.The Milling Process

- Milling is a machining process for producing flat, countered and

helical surfaces by means of multiple- cutting-edged rotating tools

called milling cutters.

- There are two different methods of metal cutting in the milling

operation

- up milling and

- down milling

The difference between these two types of operations

lies in the direction along which the work piece is fed in to the

rotating milling cutter and the direction of rotation of cutter.UP Milling

- In up milling or conventional milling, the feed direction of

the work piece is opposite to that of the cutter rotation.

- Each tooth of the cutter starts the cut with zero depth of

cut, which gradually increases and reaches the maximum

value as the tooth leaves the cut.

- The chip thickness at the start is zero and increases to the

maximum at the end of the cut.

- The surface becomes slightly wavy, as the cut does not begin

as soon as the cutter touches the work piece.UP Milling

- The resultant cutting force are directed upward and tend to lift the

work piece upward from the table, and therefore, more secured

clamping of the work piece is required.Down Milling

- Also called as Climb milling.

- The feed direction of the work piece is same as that of

the cutter rotation.

- The maximum thickness of the chip at the start of the

cut and decreases to zero thickness at the end of the cut.

- The resultant cutting forces in the down milling are

directed downward in to the machine and tend to drag

the work piece in to the cutter.

- This type of milling produces better surface finish and

dimensional accuracy.DOWN MILLINGTypes of Milling CuttersOperating Conditions in Milling

- Cutting Speed is defined as the peripheral speed of the cutter.

= πDN/1000 m/min

Where,

D = Diameter of the cutter in mm

N = Rotational Speed of the cutter in rpm

- Both N and D refer to the milling cutter in milling

- The selection of the cutting speed depends on the properties of the

material being cut, diameter and life of cutter, number of cutter teeth,

feed, depth of cut as well as width of cut and coolant used.FEED

- Feed is defined as the movement of work piece relative to the

cutter axis.

- In milling, the feed can be defined in three ways

1. Feed per tooth is defined as the distance advanced by the work

piece between the time interval when two teeth come into cutting

action.

F

1 = f / zN mm/tooth

Where,

f = feed rate in mm

Z= number of teeth on the cutter periphery

N = rpm of the cutter.2. Feed per cutter revolution F2 is defined as the distance

advanced by the work piece in the time interval when

cutter goes through one complete revolution.

F

2 = F1z mm/rev

3. Feed per minute is the distance advanced by the work

piece in on minute f.

f = F

2N = F1zNDepth of cut

- It is defined as the thickness of the layer of material

removed in one pass of the work piece under cutter. It is

expressed in mm.Width of cut

- The width of cut ω is the width of work piece surface contacting

the cutter in a direction perpendicular to the feed.Material removal rate

- It is the volume of material removed in unit time.

For milling

MRR in mm3/min

MRR = ω d f

or MRR = ω d F

2 N

or MRR = ω d F

1z NMachining time

- It is defined as the time required for one pass of width

of cut ω for milling or machining a surface and is

expressed in minutes.

Where L is the length of cut includes length of job +

length of approach + length of over travel distanceLength of cutProblem 1

- Determine the time required to mill a slot of 300 X 25 mm

in a work piece of 300 mm length with a side and face milling

cutter of 100 mm diameter, 25 mm wide and having 18

teeth. The depth of cut is 5 mm, the feed per tooth is 0.1 mm

and cutting speed is 30 m/min. assume approach and over

travel distance of 50 mm.- Given

L

j = 300 mm, D = 100 mm, w = 25 mm,

z = 18, d = 5 mm, F1 = 0.1 mm/tooth

v = 30 m/min

N = 1000 v / П D

= 100 rpm

Feed rate = feed per tooth X number of teeth on cutter X rpm

f = F

1zN = 0.1 X 18 X 100

= 180 mm/min- L1 = L2 = d(D – d)

= 22 mm

Length of cut L = Lj + L1 + approach + Over travel

= 300 + 22 + 50

= 372 mm

t = Length of cut/feed rate = L/ f = 372/180

= 2.067 min

= 2 min (app)Problem 2

- Determine the cutting time for cutting a 125 mm long

keyway using HSS end-mill of 20 mm diameter having four

cutting teeth. The depth of keyway is 4.5mm. Feed per tooth

is 0.1mm and the cutting speed is 40 m/min. assume

approach and over travel distances half of the diameter of the

cutter and a depth of 4.5 mm can be cut in one pass.- Given

Lj = 125 mm, D = 20 mm, z = 4

d = 4.5 mm, F1 = 0.1 mm/tooth,

v = 40 m/min

N = 1000 v / ПD = 636 rpm

Feed per minute = feed per tooth X no. of teeth X rpm

= 0.1 X 4 X 636

= 254.4 mm/min

Length of cut L = 125 + 10 = 135 mm

Cutting time = t = 135/254.4 = 0.53 min.Problem 3

- For a given milling operation, it was decided to switch from HSS

cutter to carbide cutter, changing the cutting speed from 35

m/min to 110 m/min. the other parameters of the cutting

operation in the two cases are:

- carbide cutter HSS Cutter

Cutter dia (mm) 150 125

Feed (mm/tooth) 0.0425 0.0375

Number of teeth 12 10- Calculate the following for each of the cutting tools

a) Cutter rpm,

b) Feed in mm/min,

c) Time required to take 200-mm long cut including approach

and over travel, and

d) Percentage saving in time by changing from HSS to Carbide

tool.Problem 3 Solution

- For HSS Cutter:

A) N = 1000 X 35/ (П X 125) = 89 rpm

B) f = F1zN = 0.0375 X 10 X 89 = 33.375 mm/min

C) t = L/f = 200 / 33.375 = 6 min

- For Carbide Cutter:

A) N = 233 rpm

B) f = F1zN = 118.8 mm/min

C) t = L/f = 1.68 min- Percentage saving in time = 6 – 1.68 /6 X100

= 72 %Problem 4

- Write down a possible sequence of operations for

manufacturing the component shown in figure. From the

stock having a length of 140 mm and 60 mm diameter.

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل محاضرة بعنوان Milling Operations - TA 102 Workshop Practice

رابط مباشر لتنزيل محاضرة بعنوان Milling Operations - TA 102 Workshop Practice

|

|