Admin

مدير المنتدى

عدد المساهمات : 18996

التقييم : 35494

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: بحث بعنوان Evaluation of Thermal Properties of E-glass/Epoxy Composites Filled by Different Filler Materials موضوع: بحث بعنوان Evaluation of Thermal Properties of E-glass/Epoxy Composites Filled by Different Filler Materials  الخميس 01 يوليو 2021, 9:42 pm الخميس 01 يوليو 2021, 9:42 pm | |

|

أخوانى فى الله

أحضرت لكم

بحث بعنوان

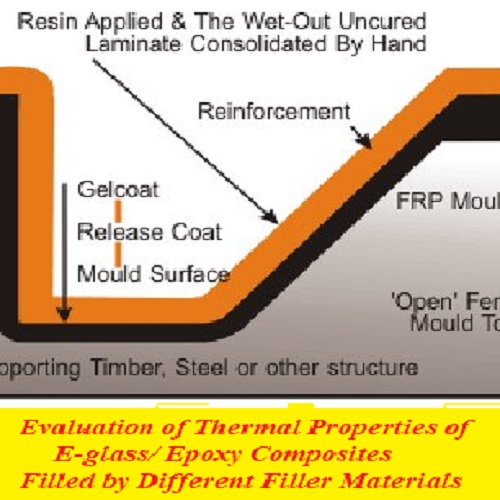

Evaluation of Thermal Properties of E-glass/ Epoxy Composites Filled by Different Filler Materials

Sachin Kumar Chaturvedi1,

1Assistant Professor,

Department of Mechanical Engineering,

Al-Falah University, Faridabad, Haryana

Email: sachin_techno@yahoo.co.in

Satendra Kumar2

2M.Tech. Research Scholar,

Department of Mechanical Engineering,

Al-Falah University, Faridabad, Haryana

و المحتوى كما يلي :

Abstract

Composites are engineered or naturally occurring materials made out of two or more constituents. To obtain the better

properties of composites material its individual constituents are modified. A composites material is difficult to carry

out due to the anisotropic and non-homogeneous structure of composites and to the high abrasiveness of their

reinforcing constituents. In this present work of the mechanical and thermal properties of E-glass/Epoxy composite

materials with fillers (Al2O3 and SiO2) has pointed to investigate the materials added to the matrix help amending the

mechanically operating properties and thermally affected of a composite. The results of various characterization tests

are reported here. This includes evaluation of tensile strength, torsion test, hardness test, thermal conductivity,

thermal expansion coefficient measurement, fire resistance test and flame propagation rate has been experimentally

recorded. As per the experimental results, this present work conclude that if we mixing 20% of Al2O3 or SiO2with 50%

of fiber and 30% of resins to make a composite material then we can easily see the SiO2have a greater mechanical

properties than Al2O3 , so this present work proposed to SiO2instead Al2O3 where the greater strength needed. It also

observed that composites filled by (20% Vol) Al2O3 and (25% Vol) SiO2exhibited low thermal conductivity it may be due

to that while heating of materials slow chemical reaction takes place in Al2O3 and SiO2and releases the small amount

of water and this released water resist the heat flow and seems possible that there is a fundamental difficult in

transferring heat from the matrix to the fibers. Increase the addition of Al2O3 and SiO2to composites reduces the

thermal expansion coefficient. It has been noticed that (25% Vol) Al2O3 and SiO2filled composite exhibited less thermal

expansion coefficient this may be by adding the more fillers in composite materials providing good filler matrix

interaction in the system, the filler binds the matrix and prevents it from expanding as much as it would on its own.

The flammability of composites is reduces when addition of thermally active fillers like oxides to the polymer matrix is

tried. From the results it is observed that increase the loading of SiO2increase the time to ignition and reduces the

flame propagation rate because Al2O3 and SiO2is active in both the condensed and gas phases of the combustion

process and it is remarkably effective in suppressing flaming combustion and smoke.

Keywords: Thermal Properties, E-Glass/Epoxy, Composite Materials

As per the above experimental results, this present work conclude the following

1. Thermal conductivity: From the obtained results it is observed that composites filled by (20% Vol)

Al2O3 and (25% Vol) SiO2 exhibited low thermal conductivity it may be due to that while heating of

materials slow chemical reaction takes place in Al2O3 and SiO2 and releases the small amount of water

and this released water resist the heat flow and seems possible that there is a fundamental difficult in

transferring heat from the matrix to the fibers.

2. Thermal Expansion Coefficient: From the experimental results it is observed that increase the

addition of Al2O3 and SiO2 to composites reduces the thermal expansion coefficient. It has been

noticed that (25% Vol) Al2O3 and SiO2 filled composite exhibited less thermal expansion coefficient this

may be by adding the more fillers in composite materials providing good filler matrix interaction in the

system, the filler binds the matrix and prevents it from expanding as much as it would on its own.

Subsequently, this would affect the thermal expansion of the composite system. The many studies

have shown that materials with higher filler content leads to a lower thermal expansion coefficient.

3. Time to Ignition and Flame Propagation Rate: The flammability of composites is reduces when

addition of thermally active fillers like oxides to the polymer matrix is tried. From the results it is

observed that increase the loading of SiO2 increase the time to ignition and reduces the flame

propagation rate because Al2O3 and SiO2 is active in both the condensed and gas phases of the

combustion process and it is remarkably effective in suppressing flaming combustion and smoke. The

main condensed phase mechanism of alumina oxide and silica oxide is the absorption of heat when

the filler decomposes.

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل بحث بعنوان Evaluation of Thermal Properties of E-glass/Epoxy Composites Filled by Different Filler Materials

رابط مباشر لتنزيل بحث بعنوان Evaluation of Thermal Properties of E-glass/Epoxy Composites Filled by Different Filler Materials

|

|