Admin

مدير المنتدى

عدد المساهمات : 18996

التقييم : 35494

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: بحث بعنوان Gearbox Dynamic Modelling موضوع: بحث بعنوان Gearbox Dynamic Modelling  الخميس 22 يوليو 2021, 1:33 am الخميس 22 يوليو 2021, 1:33 am | |

|

أخوانى فى الله

أحضرت لكم

بحث بعنوان

Gearbox Dynamic Modelling

Walter Bartelmus

Machinery Systems Division, Wrocław University of Technology

و المحتوى كما يلي :

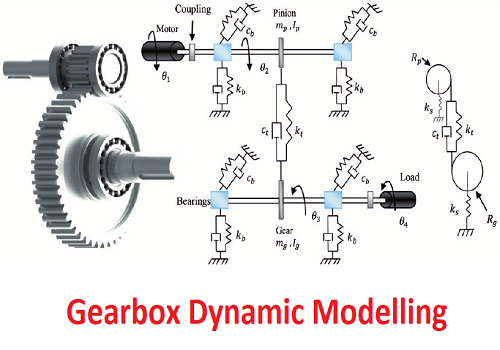

The paper reports on current developments in gearbox dynamic modelling. It refers to M¨uller’s one-mass two-parameter (stiffness and damping) gearbox model with rectilinear vibration. The paper shows that

there is a need to develop a new model, which would incorporate torsional vibration. The paper refers to the previous papers on gearbox

dynamic modelling published by the author in journals and conference

proceedings. In the present paper, the influence of the clutch damping

coefficient and one random parameter value from the three-parameter

error mode, and that of the interaction between error parameters on the

vibration generated by a gearbox system, is analyzed.

Key words: gearbox model, mathematical modelling, computer simulation.

Introduction

The modelling of gearbox dynamic behaviour belongs to the fundamental

problems of mechanical system modelling. The problem has been the subject

of many papers in Poland and abroad: Wang (1974), Mark (1978), Velex and

Maatar (1996), Smith (1998). The model presented by M¨uller in 1979 has

received a lot of attention in Poland. It was discussed, for example, by Ryś

(1977), Wilk (1981), and Dąbrowski (1992). The model is a two-parameter

(stiffness and damping) model in which the inertia of two wheels has been

reduced to one mass equivalent to a one-stage gearbox.

The author of the present paper has found that more sophisticated models are needed to describe the gearbox dynamics properly; Bartelmus (1994,

2000). Mathematical modelling and computer simulation can be applied to990 W. Bartelmus

gearbox dynamics to support diagnostic signal evaluation for diagnostic inference. This is the main aim of the present research. The computer simulation is

based on a mathematical model developed by Bartelmus (1994, 2000). General

information on gearing needed for the computer simulation of gearbox behaviour was given by Bartelmus (2000). Some results of computer simulations

supporting diagnostic inference were presented by Bartelmus (1996-1999). The

papers show that mathematical modelling and computer simulation enable the

detailed investigation of the dynamic properties of a gearing system. All the

basic factors such as: design, technology, operation and change of the gearing

system conditions which have a bearing on the vibration generated by a gearing can be investigated. The causes of vibration in gearboxes are mainly the

tooth errors and vibration is an indication of them. The computer simulation

results are referred to the laboratory investigation results presented by Rettig

(1977) and to the field measurements reported by Penter (1991), Bartelmus

(1992), and Tuma et al. (1994).

As mentioned above, the vibration of a gearbox indicates that there are

tooth errors in it. The errors appear at the production stage. The nature of

the gear-wheel interaction is such that non-linear phenomena occur caused by

friction, intertooth backlash, impact-like intertooth forces and periodic changes in tooth stiffness. As a result, the intertooth forces may exceed the force

values, which follow from the gearbox system’s rated moment. Mathematical

description enabling to include these phenomena in the equation of motion is

given by Bartelmus (2000).

The intertooth forces increase dramatically under unstable conditions. A

one-stage gear system operates under resonance conditions and is unstable

when the gearbox system’s mesh frequency is equal to its natural frequency.

In such conditions, the intertooth forces are two times greater than the rated forces. The phenomenon of resonance has not been investigated fully for

gearbox systems.

Computer simulations reveal that conditions similar to the ones occurring

at resonance may result as errors (pitting, scuffing of teeth flanks and failure of

bearings) increase during the service of a gearbox system. In the present paper,

current developments in gearbox modelling are presented with reference to the

previous papers by the present author. It is shown that a flexible clutch and an

error mode random parameter have an influence on the gearbox stability (teeth

separation). An error mode is described by several parameters, i.e. maximum

error value, shape of error plot and random error fluctuation depth.

Conclusions

The paper has shown a detailed analysis of a mutual influence of the error

mode parameters and influence of a clutch damping on a dynamic factor Kd,

which reveals the gearing condition. The error mode is described by three

parameters: a – shape parameter, e – maximum value of the error, r – scope998 W. Bartelmus

of the error random change. The analysis proves that, in general conditions

of a gearing change (change of e and r), the linear increase of Kd does not

hold, as it is stated in Bartelmus (1992) (experiment on a real object) and

1996 (computer simulation experiment). In the experiment on a real object

and in the computer simulation experiment, only the value of e was taken

into consideration.

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل بحث بعنوان Gearbox Dynamic Modelling

رابط مباشر لتنزيل بحث بعنوان Gearbox Dynamic Modelling

|

|