Admin

مدير المنتدى

عدد المساهمات : 18996

التقييم : 35494

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

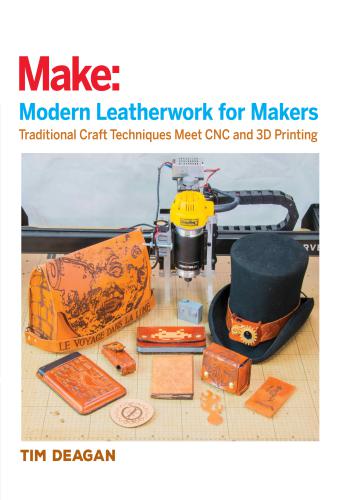

|  موضوع: كتاب Make Modern Leatherwork for Makers موضوع: كتاب Make Modern Leatherwork for Makers  الأربعاء 13 أبريل 2022, 12:47 am الأربعاء 13 أبريل 2022, 12:47 am | |

|

أخواني في الله

أحضرت لكم كتاب

Make Modern Leatherwork for Makers

Traditional Craft Techniques Meet CNC and 3D Printing

TIM DEAGAN

و المحتوى كما يلي :

Contents

About the Author v

Introduction vii

1 Understanding Leather 1

Tanning Leather 2

Understanding Hides 3

2 Fundamental Leatherworking

Tasks and Tools 7

Cutting or Removing Leather 9

Joining Leather 14

Shaping and Decorating Leather 22

3 Computer Control of Leather 31

Toolchains 34

Digital Leatherworking 39

4 3D Printing Leatherworking Tools 43

Additive Manufacturing Techniques 44

The 3D Printing Toolchain 48

3D Printed Leatherworking Tools 56

5 The Fractal Journal Cover 63

Design 64

Digital Laser Fabrication 67

Leatherworking 81

The Results 85

Enhancements 85

6 The Ghouls and Gears Multi-Tool

Holder 89

Design 90

Digital Laser Fabrication 93

Leatherworking 102

7 Steampunk

Action-Cam Top Hat 111

Design 112

Digital Fabrication 116

Leatherworking 119

The Results 126

Enhancements 127

8 8-Bit Cell Phone Belt Case 129

Design 130

Digital Fabrication 136

Leatherworking 145

The Results 152

9 PCB Tablet Sleeve 155

Design 156

Digital Fabrication 161

Leatherworking 171

The Results 173

10 Elder Gods Belt Pouch 175

Design 176

Digital Fabrication 182

Leatherworking 187

The Results 190

11 Le Voyage dans la Lune

Shoulder Bag 193

Design 194

Digital Fabrication 199

Leatherworking 203

The Results 209

A Appendix: Online Resources 211

Leather 211

Hardware 212

Software 213

Digital Fabrication 214

Index

Index

Numbers

2D and 3D machining, 34–35

2-flute straight end mill, 157

2.5 W laser engraving machine, 212

3D model, 35

3D printed tools, designing, 59–60

3D printers, 32

3D printing. See also printing

additive manufacturing techniques, 44–48

arbor press, 57

bevel cutter, 60

blades, 59–60

controller software, 37

holsters, 58

leather cases, 58

leatherworking tools, 56–61

molds, 58–59

organizational tools, 60–61

post-processing coatings, 58

powders, 44

“slicer” program, 36

stamps, 56–58

toolchain, 48–55

3DBenchy, 45

8-bit cell phone belt case

1/18” ball end mill, 137

3D printed frame, 132–133

alien pattern insets, 133

attaching spring clip, 147–149

back flap, 134

clean up and trim, 145–146

clip cover, 135

color and finish, 146–147

design, 130–131

digital laser fabrication, 136–145

double-sided tape, 139

dye beading on vinyl, 147

finishing, 152–153

frame model, 144–145

front, 133–134, 152

gap around phone, 132

inside and back, 153

knives, 142

leather held for milling, 139

leather pattern, 133–136

leather sections, 133

masking and spraying adhesive, 139

midline on frame, 132

phone dimensions, 132

pieces laid out for cutting, 136

prepping folds, 146

rivets on clip cover, 148

sewing closures, 149–150

sewing covers, 150–151

Silhouette model, 141

stitching hole order, 149

stitching through frame, 131

taking measurements, 131–132

VCarve simulation preview, 138

15 W TTL-enabled focusing laser, 212216 Index

A

ABS filament, 46

action cam, 112

additive manufacturing, 32, 44

Adobe Creative Suite software, 213

airbrush kit, 83–84

aliasing, 201

alien pattern

insets, 133

stencil, 141–144

alignment, holding, 207

All3DP digital fabrication, 214

Altoids tin, 176 tin, 176

antiquing gels, 82

anvils, 105

arbor press, 57

artwork, creating, 180

ASA filament, 47

Autodesk Fusion 360 Fusion 360 , 35, 50, 68 , 35, 50, 68

Autodesk TinkerCAD, 49–50, 213

awls, 15–16

B

back-stitching, 28

belly of hide, 4

belt pouch

clean up and trim, 187–188

color and finish, 188–189

creating Cthulhu, 180–181

cutting away fibers, 188

digital laser fabrication, 182–187

finishing, 190–191

grooves cut, 186

holes and outline, 185

image toolpath, 184

leather workpiece, 184

pattern, 176–180

preparing files, 182–187

setting snaps, 189

stitching, 189

taking measurements, 176

X0Y0, 187

bend of hide, 4

beveling

and edging, 14

tools, 59, 60–61

blades, 59–60

boosh controller PCB, 157–158

boundary definition, 52–53

box cutters, 10

brain tanning, 2

break-in, accelerating, 85–86

BS (acrylonitrile butadiene styrene), 46

buckles and rings, 19–20

burn pattern, multi-tool holder, 96

burning

and engraving, 169–170

operations, 200–202

button hole, punching, 208

buttons and studs, 20–21

C

CAD (computer assisted design), 34–35. See also

sheet metal CAD

Cahier, 63–64

calipers, 112

camera model, 112, 114, 119

carbon fiber filament, 46

carbon stains, avoiding, 80

cardboard check, running, 78

Cartesian machine, 33

carving and tooling, 23

cell phone belt case

1/18” ball end mill, 137

3D printed frame, 132–133

alien pattern insets, 133

attaching spring clip, 147–149

back flap, 134

clean up and trim, 145–146

clip cover, 135

color and finish, 146–147

design, 130–131

digital laser fabrication, 136–145

double-sided tape, 139Index 217

dye beading on vinyl, 147

finishing, 152–153

frame model, 144–145

front, 133–134, 152

gap around phone, 132

inside and back, 153

knives, 142

leather held for milling, 139

leather pattern, 133–136

leather sections, 133

masking and spraying adhesive, 139

midline on frame, 132

phone dimensions, 132

pieces laid out for cutting, 136

prepping folds, 146

rivets on clip cover, 148

sewing closures, 149–150

sewing covers, 150–151

Silhouette model, 141

stitching hole order, 149

stitching through frame, 131

taking measurements, 131–132

VCarve simulation preview, 138

channels, cutting, 81–82

Chartres Cathedral labyrinth, 65

chisels, 16

chrome tanning, 2, 5

clasps and hooks, 20

cleaning filament, 47

clips, using to mold leather, 23

closure stud, attaching for shoulder bag, 208

closures

fractal journal cover, 87

types, 19–21

CNC (computer numeric control). See also

G-code

Cartesian machine, 33

router, 33

toolpath, 36

CNC Cookbook, 214

CNC drag knife, 142

CNC operations

materials, 39

tablet sleeve, 166–170

CNC swivel knife, 12

collagen fibrils and fibers, 1–2

color and finish

cell phone belt case, 146–147

fractal journal cover, 82–84

multi-tool holder, 102–104

color changing filament, 47

conchos and spots, 22

conditioners, 86

conductive filament, 47

constructing images and models, 34–35

controllers, 36–37, 55

copper layers, 158–159

copper rivets and washers, 18

corium, 2

corners, cutting, 86–87

Cricut hardware, 212

CSG vs. mesh model, 58–59

Cthulhu, 175, 180–181, 183–184, 187

Cura software, 213

curing resin, 45

curved lines, measuring, 197

cutting

corners, 86–87

fold groove, 81

leather, 9–14

multi-tool holder, 101

stitching groove, 82

threads, 29

D

decorating leather, 22–29

digital calipers, 112

digital imagery, multi-tool holder, 91–92

digital laser fabrication

3D printed parts, 163–164

attaching spring clip, 147–148

cardboard check, 78

clean up and trim, 80, 101–102, 119–121,

145–146

CNC operations, 166–170218 Index

CNC work, 136–137, 184–186

color and finish, 121–124, 146–147

contact-paper layer, 167

cover burn plan, 70–71

cover cut plan, 69

cutting, 76–81, 101

cutting consistency, 76

cutting out pieces, 139

cutting pattern stencil, 141–144

dimensions, 70

DXF (Drawing Exchange Format), 76, 94

DXF editor, 84

engraving, 79–81, 101

engraving and burning, 169–170

explained, 32–33

extruding, 94–95

focusing laser, 76

G-code, 72

homing machines, 71

images, 163

laser cutting and burning, 117–118

laser work, 187

layout guide, 74

leather shrinkage, 77

machine setup, 71, 73–74

making gears, 118–119

making rough cuts, 75

manual position setting, 73

manual stitching-holds, 68

milling and drilling, 168–169

molding leather, 164–165

mounting gears, 126

optimized toolpath, 69

orienting workpiece, 167

pocket cut plan, 70

pocket piece, 75

preparing files, 67–70, 93–101, 116, 182–184

prepping folds, 146

prepping workpiece, 74–76, 100–101,

116–117, 184

prepping workpieces, 137–139

printing camera model, 119

printing frame, 144–145

pulsing and jogging laser, 74

resources, 214

riveting gears, 125–126

setting eyelets, 125–126

setting machine origin, 73

sewing closures, 149–150

sewing corners, 124–125

sewing covers, 150–151

sleeve parts, 161–163

steampunk action-cam top hat, 116–119

tablet sleeve, 161–170

toolpath spaghetti, 68

unfolding, 179

workholding sandwich, 167

x-carriage, 73

x-gantry, 73

digital leatherworking, 39–41

dimensions, handling, 70, 99

Donek drag knife, 212

double bend of hide, 4

double shoulder of hide, 4

drive punch, 13

DXF (Drawing Exchange Format), 35, 68, 76

DXF editor, using, 84

DXF files, steampunk action-cam top hat, 116

dyeing leather, 82–83, 103, 122, 147, 168, 206

E

Easel CAD/CAM tool, 136

edge roller, 172

edging and beveling, 14

elder gods belt pouch. See pouch

ELE Explorer action cam, 112

embroidery scissors, 9

engraving

and burning, 169–170

fractal journal cover, 79–80

multi-tool holder, 101

with shades of gray, 194

extruding, 94–95

eyelets, 17–18

setting, 125–126Index 219

F

fibers

cutting away, 188

filing, 145

filament characteristics, 46–48

fillet, measuring, 160

Fine Leatherworking, 211

finish and color, 82–84, 102–104

flesh, 2

flexible TPE/TPU filament, 46

fold groove, cutting, 81

folds, prepping, 146

forked chisels, 16

FPE filament, 48

fractal journal cover

accelerating break-in, 85–86

Chartres Cathedral labyrinth, 65

cleanup and trim, 80

closure, 87

closures, 87

color and finish, 82–84

cover pattern, 66

cutting, 76–81

cutting channels, 81–82

cutting corners, 86–87

digital imagery, 65–66

digital laser fabrication, 67

engraving, 76–81

extending, 87

finishing, 85

fold allowance, 64

G-code, 72

Julia set, 66

leather pieces, 65

machine setup, 71, 73–74

Mandeltree, 65

pattern, 64–65

preparing files, 67–70

prepping workpiece, 74–76

raster images, 67

results, 85

snaps and studs, 87

stitching, 84–85

frame model, 144–145

fritzing layer options, 158

full grain leather, 3

Fusion 360 software, 35, 50, 68, 213

G

G-code. See also CNC (computer numeric

control)

digital laser fabrication, 72

features, 36–37

simulator, 68

G-Code Q’n’dirty toolpath simulator, 213

gear model, 114

gears

making for steampunk top hat, 118–119

mounting, 126

painting, 124

riveting, 125–126

genuine leather, 3

Gerber files, 158

GIMP (GNU Image Manipulation Program), 34,

194–195

glow-in-the-dark filament, 47

glue, 21

gouging and grooving, 13

grains of leather, 2–3

gray levels, 194–195

grommets, 17–19

grooving and gouging, 13

H

hammering, 105

hammering metal, 13

hand punch, 16. See also punching

Handibot hardware, 212

hand-stitching, 14–15, 24–29

hatband model, 113. See also steampunk actioncam top hat

head knife, 10

hides, 3–5

HIPS filament, 46

hole order, stitching, 149220 Index

holes

even patterns, 15–16

getting needles through, 28

making, 12

punching, 26

shrinkage, 80

holsters, 58

homing machines, 71

hooks and clasps, 20

hydrophilicity, 40

I

image, engraving with shades of gray, 194

image, constructing, 34–35

Inkscape program, 34, 180, 213

J

joining leather, 14–21

journal cover

accelerating break-in, 85–86

Chartres Cathedral labyrinth, 65

cleanup and trim, 80

closure, 87

closures, 87

color and finish, 82–84

cover pattern, 66

cutting, 76–81

cutting channels, 81–82

cutting corners, 86–87

digital imagery, 65–66

digital laser fabrication, 67

engraving, 76–81

extending, 87

finishing, 85

fold allowance, 64

G-code, 72

Julia set, 66

leather pieces, 65

machine setup, 71, 73–74

Mandeltree, 65

pattern, 64–65

preparing files, 67–70

prepping workpiece, 74–76

raster images, 67

results, 85

snaps and studs, 87

stitching, 84–85

Julia set, fractal journal cover, 66

K

KISSlicer software, 213

knives

CNC drag vs. stencil cutter, 142

and scissors, 9–10

L

laser alternatives, 182, 201

laser fabrication. See digital laser fabrication

laser pattern, aligning, 200

laser sintering, 44

laser tool, using, 71, 74–75

leather

conditioners, 86

cutting, 9–14

dyeing, 82–83

grades, 2

holding while sewing, 27

hydrophilicity, 40–41

inconsistencies, 41

irregularities, 92

joining, 14–21

molding, 40

properties, 39–40

quality, 4–5

versus rawhide, 3

recycling, 5

removing, 9–14

salvaging, 5

shaping and decorating, 22–29

shrinkage, 77

softening, 85–86

staining, 82

suntanning, 41

surprises, 41Index 221

thickness, 40

thicknesses, 3–4

weight, 4

leather cases, 58

leather pattern, multi-tool holder, 90–91.

See also patterns

Leatherman Wave , 90 , 90

leather-stitching needle, 17

Leatherworker.net, 211

leatherworking

attaching closure stud, 208

attaching spring clip, 147–148

clean up and trim, 119–121, 145–146, 171,

187–188

color and finish, 82–84, 102–104, 121–124,

146–147, 188, 206

cutting channels, 81–82

cutting corners, 86

finish coat, 171

making straps, 203–206

prepping folds, 146

riveting, 106–108, 125–126, 206–207

setting eyelets, 125–126

setting snaps, 104–106, 189

sewing closures, 149–150

sewing corners, 124–125

sewing covers, 150–151

stitching, 84–85, 189, 206–207

tablet sleeve, 171–172

leatherworking tools. See also multi-tool

holder

beveling and edging, 14

caution, 9

grooving and gouging, 13

knives and scissors, 9–10

punches, 12–13

resource, 8

skiving, 11

storing, 60

swivel knives, 11–12

LED diode lasers, overheating, 201

lignin (bioFila) filament, 46

Line 20 snap, 19

line segments, joining, 97

liquids, printing with, 45

M

machines, homing, 71

machining modes, 34–35

magnetic filament, 47

magnetic snaps, 149. See also snaps

and studs

magnets, 21

Maker resources, 214

Mandelbrot, Benoit, 65

Mandeltree, 65

manufacturing tools, 32

measurements

cell phone belt case, 131–132

steampunk action-cam top hat, 112–114

tablet sleeve, 160

mechanical iris, 127

Méliès, Georges, 193

mesh modeling, 52–53

mesh vs. CSG model, 58–59

Meshmixer software, 213

metal filament, 46

metal on mental, caution, 13

metal stamps, 57–58

metallic powders, 44

milled leather, 139, 159

milling and drilling, 168–169

miter, splitting model with, 178–179

model, constructing, 34–35

modeling objects

Autodesk Fusion 360 , 35, 50, 68 , 35, 50, 68

Autodesk TinkercCAD, 49–50

boundary definition, 52–53

mesh modeling, 52–53

overview, 58–59

OpenSCAD, 51–52, 113, 213

molding leather, 22–23, 40

molds, 3D printing, 58–59

Moleskine Cahier, 63–64

motor, moving by steps, 38222 Index

multi-tool holder. See also leatherworking

tools

applying resist, 103–104

burn pattern, 96, 98

burning gears, 102

clean up and trim, 101–102

clipped gears, 98

cut pattern, 91

cutting, 101

digital imagery, 91–92

digital laser fabrication, 93–102

engraving, 101

filled pattern outline, 97

finishing, 109

gears and skull, 99

gears positioned, 97

joining line segments, 97

leather pattern, 90–91

leatherworking, 102–104

nested patterns, 100

overlapping sections, 100

preparing files, 93–100

prepping workpiece, 100–101

results, 109

riveting, 106–108

setting snap, 104–106

skull image, 92, 94

unjoined line segments, 96

N

NC (numeric control), 31, 72

needles

getting through holes, 28

for hand-stitching, 25, 27–28

for holding alignment, 207

using, 16–17

nGen filament, 47

notebook. See fractal journal cover

nylon filament, 46

O

OpenSCAD software, 51–52, 113, 213

organizational tools, 60–61

overlapping sections, 100

P

Parsons, John, 31

patterns, nesting, 100. See also leather pattern

PC polycarbonate, 46

PC/ABS filament, 47

PCB layers, 158

PCB tablet sleeve. See boosh controller PCB;

tablet sleeve

PCB traces, milling, 170

Pen tool, 180

PET (CEP) filament, 46

PETG (XT, n-vent) filament, 46

PETT (tglase) filament, 47

pill bottle storage system, 60

Piñatex , 3 , 3

PLA (polylactic acid), 46

plastic filament, printing with, 45–48

pleather, 3

PMMA, acrylic filament, 47

PNG format, 35

pocket edge, stitching, 206

polymerization, 45

POM, acetal filament, 47

PORO-LAY filament, 48

posterized image, 195

pouch

clean up and trim, 187–188

color and finish, 188–189

creating Cthulhu, 180–181

cutting away fibers, 188

digital laser fabrication, 182–187

finishing, 190–191

grooves cut, 186

holes and outline, 185

image toolpath, 184

leather workpiece, 184

pattern, 176–180

preparing files, 182–187

setting snaps, 189

stitching, 189Index 223

taking measurements, 176

X0Y0, 187

powders, printing with, 44

PP filament, 47

printing. See also 3D printing

frame, 144–145

with liquids, 45

with plastic filament, 45–48

with powders, 44

Printrbot hardware, 212

Pronterface software, 213

Prusa i3 MK2 hardware, 212

pulse train, 38–39

punching. See also hand punch

button hole, 208

explained, 12–13

holes, 26

PVA filament, 46

PWM (pulse width modulation), 194–195

Q

quality of leather, 4–5

R

Rapid Rivet, 18–19

raster images, 34–35, 67

rawhide, 3

Raynaud, Nicolas, 68

recycling leather, 5

removing leather, 9–14

Repetier software, 213

RepRap G-code program, 72

resin printing, 45

resist

applying, 103–104

leaking, 143

resources. See websites

Rhino software, 213

rings and buckles, 19–20

riveting

explained, 106–108

gears, 125–126

shoulder bag, 206–208

rivets, 17–19, 148

rotary knives, 10

rotary punch, 12

round knife, 10

router, 33

rubber stamps, 57–58

S

saddle stitch, 15, 24–29, 150. See also

stitching

salvaging leather, 5

sandstone (LAYBRICK) filament, 47

scissors and knives, 9–10

screw post, 17

screws, 17–19

sections, overlapping, 100

servos, 37

setting snap, 105–106

sewing awl, 16

sewing leather, 14–17

Shapeoko hardware, 212

shaping leather, 22–29

shears, 9

sheet metal CAD, 177. See also CAD (computer

assisted design)

ShopBot hardware, 212

shoulder bag

aligning laser pattern, 200

attaching closure stud, 208

burning operations, 200–202

burning strap, 202

color and finish, 206

cutting and drilling, 199–200

design, 194–199

digital laser fabrication, 199–202

drilling holes for pocket, 200

dyeing, 206

finishing, 209

Le Voyage dans la Lune, 193

making strap, 203–206224 Index

posterized image, 195

punching button hole, 208

PWM (pulse width modulation), 194–195

stitching and riveting, 206–208

stitching pocket edge, 206

shoulders of hide, 4

side of hide, 4–5

Silhouette model, 141

Silhouette stencil cutter, 212

silkscreen layer, 159, 170

single shoulder of hide, 4

sintering, 44

skiving. See also thickness of hide

explained, 11

strap for shoulder bag, 204

skull image, 92, 94–95

Slic3r software, 213

“slicer” program, 36

slicing, 53–55

snap-blade knives, 10

snaps and studs. See also magnetic snaps

setting, 189

stitching, 150

using, 19, 87, 104–106

sockets, setting, 106

softening leather, 85–86

split of hide, 4

spoil board, surfacing, 140–141

spots and conchos, 22

spring clip, attaching, 147–148

spring punch, 12

staining leather, 82

stair-stepping, 201

stamp punch, 13

stamping, 24, 105

stamps, 3D printing, 56–58

steampunk action-cam top hat

#2 and #3/0 brushes, 123

3D printed pieces, 123–124

applying dye, 122

clean up and trim, 119–121

color and finish, 121–124

cutting grooves, 120

digital laser fabrication, 116–119

edge trimming, 120

enhancements, 127

finishing, 126–127

gears, 118–119

groove locations for folding, 120

leather pattern, 114–115

leather placed for cutting, 117

mounting gears, 125

painting gears, 124

painting pattern, 122

pattern check, 117

pattern test, 114

resisting pattern parts, 122

riveting gears, 125–126

scanned border pattern, 115

setting eyelets, 125–126

sewing corners, 124–125

stitching holes, 125

stitching pattern, 125

taking measurements, 112–113

work blank, 117

wrapping edge, 121

stencil cutter knife, 142

stencil pattern, cutting, 141–144

step and direction commands, 37–39

stepper motors, 37–39

stitches, pulling tight, 28

stitching. See also saddle stitch

explained, 84–85

from front to back, 207

hole order, 149

pattern, 125

pocket edge, 206

pouch, 189

shoulder bag, 206–208

snaps, 150

tablet sleeve, 171

stitching groove, 13, 82

stitching holes

clearing, 80

marking, 125

stitching pony, 27Index 225

STL files, steampunk top hat, 116

Stohlman, Al, 8, 15, 29

strap for shoulder bag

beveling edge, 205

burning, 202

Conway buckle, 205

making, 203–206

skiving, 204

studs

and buttons, 20–21

and snaps, 87, 105

subtractive manufacturing tools, 32

suede, 2

suntanning leather, 41

surfacing tables and boards, 140–141

SVG format, 35

swivel knives, 11–12, 61

T

T2Laser software, 213

tablet sleeve

2-flute straight end mill, 157

art, 157–160

boosh controller PCB, 157

clean up and trim, 171

contact-paper layer, 167

copper layers, 158–159

design, 156

digital laser fabrication, 161–170

edge coating, 172

finish coat, 171

finishing, 173

fritzing layer options, 158

Gerber files, 158

milled leather, 159

sewing and finishing, 171–173

silkscreen layer, 159

stitching, 171

structure, 156–157

taking measurements, 160

traces, 158

Tandy Leather, 8, 211

tanning leather, 2–3

thickness of hide, 4, 40. See also skiving

Thingiverse digital fabrication, 214

threads

cutting, 29

for hand-stitching, 25–26

TinkerCAD software, 49–50, 213

toggle button, 20

toolchains, 34–39, 48–55

tooling and carving, 23

toolpaths, generating, 35–37, 136

tools. See leatherworking tools

top grain, 3

top hat. See steampunk action-cam top hat

TPC filament, 47

TPE/TPU filament, 46

traced vector files, cleaning up, 95. See also

vector images

traces, 158, 169

trimming corners, 86–87

tubular rivets, 18, 106–107, 148

U

Universal Gcode Sender software, 213

utility knives, 10

V

VCarve simulation preview, 138

vector images, 34. See also traced vector files

vegetable tanning, 2–3, 40

Venturi effect, 83

Vetric VCarve Pro, 136

V-gouges, 13, 81–82

vinyl cutter swivel knife, 12

W

water, 40

wax (MOLDLAY) filament, 47

Weaver Leather Supply, 211

websites

2.5 W laser engraving machine, 212226 Index

15 W TTL-enabled focusing laser, 212

Adobe Creative Suite software, 213

All3DP digital fabrication, 214

CNC Cookbook, 214

Cricut hardware, 212

Cura software, 213

digital laser fabrication, 214

Donek drag knife, 212

Fine Leatherworking, 211

Fusion 360 software, 213

G-Code Q’n’dirty toolpath simulator, 213

Handibot hardware, 212

Inkscape program, 213

KISSlicer software, 213

Leatherworker.net, 211

Maker resources, 214

Meshmixer software, 213

OpenSCAD software, 213

Printrbot hardware, 212

Pronterface software, 213

Prusa i3 MK2 hardware, 212

Repetier software, 213

Rhino software, 213

Shapeoko hardware, 212

ShopBot hardware, 212

Silhouette stencil cutter, 212

Slic3r software, 213

T2Laser software, 213

Tandy Leather, 211

Thingiverse digital fabrication, 214

TinkerCAD software, 213

Universal Gcode Sender software, 213

Weaver Leather Supply, 211

X-Carve CNC hardware, 212

XTC-3D coating, 58

Zack White Leather Co., 211

weight of hide, 4

Wikimedia.org, 141

wood filament, 46

work areas, handling, 99

work table, surfacing, 140–141

X

X0Y0, determining for belt pouch, 187

x-carriage, digital laser fabrication, 73

X-Carve CNC hardware, 212

x-gantry, digital laser fabrication, 73

XTC-3D coating, 58

Z

Zack White Leather Co., 211

ZO position, finding, 185–186

Z-probe, 185

Appendix:

Online Resources

Leather

Tandy Leather

tandyleatherfactory.com

Online vendor of leather and

leatherworking tools

Leatherworker.net

leatherworker.net

Essential online leatherworking

community and forum

Weaver Leather Supply

weaverleathersupply.com

Online vendor of leather and

leatherworking tools

Zack White Leather Co.

zackwhite.com

Online vendor of leather and

leatherworking tools

Fine Leatherworking

fineleatherworking.com

Online vendor of leather and

leatherworking tools

The Leathercraft Guild

theleathercraftguild.com

Supporting leatherwork

since 1949212 Appendix: Online Resources

Hardware

X-Carve CNC

inventables.com

X-Carve CNC manufacturer

Handibot

shopbottools.com

Handibot manufacturer

Prusa i3 MK2

prusa3d.com

Prusa i3 MK2 manufacturer

Printrbot

printrbot.com

Printrbot 3D printer manufacturer

2.5 W laser engraving machine

gearbest.com

Online supplier of tools and import items

(2.5 W laser)

15 W TTL-enabled Focusing Laser

aliexpress.com

Online supplier of tools and import items

(15 W laser)

Donek Drag Knife

donektools.com

CNC drag knife

Silhouette Stencil Cutter

silhouetteamerica.com

Vinyl and paper stencil cutters

ShopBot

shopbottools.com

CNC routers

Shapeoko

https://carbide3d.com/shapeoko/

CNC routers

Cricut

cricut.com

Vinyl and paper stencil cutters

Software 213

Software

Slic3r

slic3r.org

Slic3r slicing program

Pronterface

pronterface.com

3D printer control program

Fusion 360

https://www.autodesk.com/products/

fusion-360/students-teachers-educators

3D modeling and simulation

OpenSCAD

openscad.org

3D modeling software

T2Laser

t2laser.t2graphics.com

GRBL laser engraver control software

TinkerCAD

tinkercad.com

3D modeling software

Universal Gcode Sender

https://winder.github.io/ugs_website/

GRBL G-code sending program

G-Code Q'n'dirty toolpath simulator

https://nraynaud.github.io/webgcode/

G-code simulation

Inkscape

inkscape.org

Vector drawing program

Cura

https://ultimaker.com/en/products/

cura-software

3D slicing software

Repetier

repetier.com

3D slicing and control software

KISSlicer

kisslicer.com

3D slicing software

Meshmixer

meshmixer.com

Mesh creation and editing

Rhino

rhino3d.com

High-end 3D modeling using boundary

definition

Adobe Creative Suite

Adobe.com

Industry-standard drawing, photography,

and video tools

214 Appendix: Online Resources

Digital Fabrication

Thingiverse

thingiverse.com

Vast collection of 3D models

All3DP

all3dp.com

Fantastic online 3D printing magazine

CNC Cookbook

cnccookbook.com

Fantastic CNC blog and information

Make:

makezine.com

All-around Maker resources

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل كتاب Make Modern Leatherwork for Makers

رابط مباشر لتنزيل كتاب Make Modern Leatherwork for Makers

|

|