Admin

مدير المنتدى

عدد المساهمات : 18992

التقييم : 35482

تاريخ التسجيل : 01/07/2009

الدولة : مصر

العمل : مدير منتدى هندسة الإنتاج والتصميم الميكانيكى

|  موضوع: بحث بعنوان Auxetic Composites in Aerospace Engineering موضوع: بحث بعنوان Auxetic Composites in Aerospace Engineering  الخميس 01 أبريل 2021, 1:02 am الخميس 01 أبريل 2021, 1:02 am | |

|

أخوانى فى الله

أحضرت لكم كتاب

بحث بعنوان

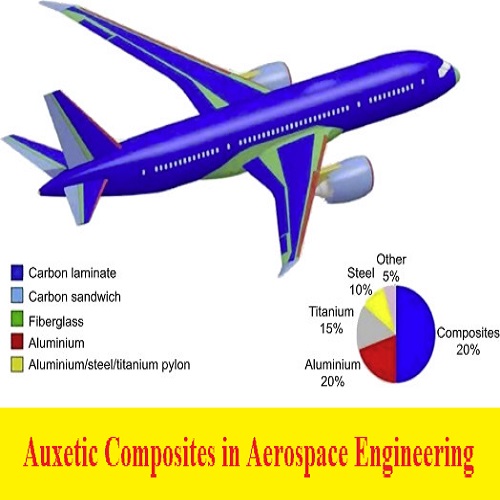

Auxetic Composites in Aerospace Engineering

Z. Wang, A. Zulifqar, H. Hu

Hong Kong Polytechnic University, Kowloon, Hong Kong

و المحتوى كما يلي :

Introduction

As we know, most materials laterally shrink when stretched and laterally expand when

compressed in the longitudinal direction, that is, they have a positive Poisson’s ratio

(PR). The common example of rubber can be quoted; it becomes thinner when

stretched. In contrast, there are some special materials which possess negative PR

(ie, they laterally expand when stretched or laterally shrink when compressed in the

longitudinal direction). The materials with negative PR are also called ‘auxetics’

(Evans et al., 1991), which originated from the Greek word auxetos meaning ‘that

which may be increased’. Auxetic materials can be found among natural materials

such as rocks, minerals, skin and others. They can also be produced synthetically.

To date, many auxetic materials have been made including auxetic foams such as polyurethane (Lakes, 1987), polytetrafluoroethylene (PTFE) (Caddock and Evans, 1989)

and ultra-high-molecular-weight polyethylene (Alderson and Evans, 1992); auxetic

textiles such as fibres (Ravirala et al., 2006, 2005; Alderson et al., 2002), yarns (Sloan

et al., 2011) and fabrics (Wang and Hu, 2014; Liu et al., 2010; Ge and Hu, 2013;

Ugbolue et al., 2011; Hu et al., 2011); auxetic composites and so on.

Auxetic materials have many enhanced properties compared to conventional materials. Auxetic materials have higher shear modulus, enabling auxetic materials to have

better shear resistance. Auxetic materials have a double-curved (synclastic) property,

that is, when fixed on a curved surface, the materials form a dome shape instead of the

saddle shape (anticlastic) that conventional materials may form. Auxetic materials

have enhanced indentation resistance and energy absorbance properties. When

conventional materials are subject to an impact force, the materials flow away from

the impact point, whereas the auxetic materials flow into the impact point when subject

to an impact force, which makes the auxetic materials harder to be indented. Auxetic

materials also have other advantages, such as enhanced fracture toughness, enhanced

crack growth resistance and so on.

Due to the enhanced properties that auxetic materials possess, auxetic composites have better performance than conventional composites and have some

special applications. In this chapter, the auxetic composites and their applications will be discussed in detail, especially the applications in aerospace engineering.

Conclusions

This chapter mainly discussed the use of auxetic composites in aerospace engineering.

The auxetic composites are very good materials to be used in aircraft due to the advantages they possess. The advantages make them very useful in each part of the aircraft.

For example, enhanced damping resistance can be used on the aircraft head to increase

the damping property of it. Although this new breed of composites is not yet mature

enough, it is believed that they will be developed and good enough to be used in aerospace engineering instead of conventional composites.

كلمة سر فك الضغط : books-world.net

The Unzip Password : books-world.net

أتمنى أن تستفيدوا من محتوى الموضوع وأن ينال إعجابكم

رابط من موقع عالم الكتب لتنزيل بحث بعنوان Auxetic Composites in Aerospace Engineering

رابط مباشر لتنزيل بحث بعنوان Auxetic Composites in Aerospace Engineering

|

|